Safety

Our Safety

Morrows Logistics is committed to ensuring a safe and healthy working environment for personnel in our offices, workshops and workplaces. We believe all work-related injuries and property losses are preventable, and that safety is good business. Morrows also believes that there is no more important factor in the undertaking of anyone’s job than the prevention of injury or ill health to any people in our workplace, or workplaces visited by our personnel.

To achieve a safe and healthy working environment within Morrows, the commitment and cooperation of our personnel and visitors is essential.

No task is so important as to compromise health and safety. Appropriate consideration must be given to determining a safe and healthy work method for each and every activity.

Key aspects of our safety system include:

|

Emergency Training

In addition to the training as part of their Dangerous Goods licensing, Morrows drivers, along with our team of freight-handlers, participate in mock training exercises. In the unlikely event that something goes wrong, hands-on training ensures the team are prepared to handle an emergency.

Spill Kits

Every truck in the Morrows fleet carries a spill kit. In the event of an emergency, the spill kit contains the equipment required to clean up a small spill, or to contain a larger loss.

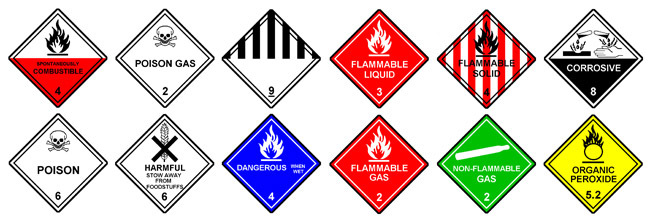

Dangerous Goods Licensing

Our drivers and company fleet are licensed through WorkSafe to transport bulk dangerous goods. For our driver team, that means a two-day course which thoroughly covers the safety and legal responsibilities when it comes to carrying dangerous goods chemicals.

Drivers have regular refresher training and medicals to ensure they are both competent and fit for duty.

Sub-Floor System

Any new truck joining the company fleet over the past 3 years has been built with a sub-floor to capture any spills. Any liquid spilt onto the floor of the freight area is captured and drains into a holding tank under the truck.

Driver Training

The driving skills of newly employed drivers at Morrows is assessed by an experienced operator as part of the pre-employment process. Once on board with the Morrows team, drivers initially receive on-the-road training in all aspects of the role with our experienced operators. Drivers then receive ongoing training as they further their careers with Morrows.

Fatigue Management

Morrows Logistics, and the majority of our driver group, are accredited under the government’s Basic Fatigue Management (BFM) scheme. This allows drivers to work longer days, whilst still remaining safe.

To meet the criteria for the accreditation, the company is audited to ensure we have systems in place to manage our compliance with the scheme, whilst the drivers must complete a training course and pass strict medical examinations on a regular basis.

Dash Cams

Many of our trucks are fitted with both front and rear Dash Cams for added driver security and protection. Footage is able to be retrieved in real time before the driver even returns to the depot. Footage is stored on our secure servers and can be retrieved at a later date should the need arise.

Get in touch with us and you will see the benefits of partnering together with us!

Contact UsSafety Video

Click to watch a short video from our owner, David Morrow, taking the drivers through chemical spill training! David is reinforcing the commitment that Morrows has in developing the team to operate at the highest standards possible and this starts from the owner delivering training so he can set the safety standard.